We are a Printing Company that Challenges New Frontiers.

The Kowabo Co., Ltd. Printing Business Division is a printing company that challenges new frontiers.

As a printing company, in addition to developing our in-house printing and processing technologies, we constantly strive to challenge creation of new business.

We are currently tackling the following four challenges.

- Package printing resulting from original printing and processing technological development

- Printing of soft packaging materials using UV flexographic printing

- Import business of products such as ornamental boxes and pouches utilizing certified factories located overseas

- "Total package" business proposed by a printing company

The Printing Business Division has accumulated know-how centered on pharmaceutical and foodstuff packaging in its factories many years. Based on this know-how, we will continue to challenge new fields ranging from "paper carton package printing" to "soft packaging material printing", "overseas production", and "total package business".

To delight our customers, we always remain aware of "cost" and propose quality products. We have acquired ISO 9001 certification.

Corporate Vision

In the history of more than 100 years since its founding in 1894, the Kowa Group has developed a variety of businesses in a wide range of countries and regions based both on the steady spirit of manufacturing and the challenging spirit of enterprise which always captures the changing times. We aim to pursue the happiness of people throughout the world and realize their healthy and prosperous living.

Quality Policy

We shall be awafre of clients' needs, and shall continue to supply products that satisfy our clients.

To achieve this, we shall promote the following activities:

- We shall strive to understand customer needs relating to quality, costs, delivery, technology, etc.

- We shall quickly analyze clients' claims and shall strive to prevent re-occurrences.

- We shall build a quality management system through the originality and ingenuity and active participation by all our staffs, and shall strive to make continual improvements.

- We shall actively promote quality improvement activities, and shall resolve problems through the participation of all our staffs.

Organizational Skills that Create High Quality

Kowabo Co., Ltd. Printing Business Division is the organization which mainly engages in the manufacture and sales of packaging materials.

To enable the manufacturing and selling of high quality materials relating to pharmaceutical, healthcare and other products within Kowa Group and requested by customers outside the Group, Printing Business Division consists of Manufacturing and Development Department which conducts printing and processing, Quality Assurance Department that implements quality control and quality assurance, Sales Department which is in charge of activities from materials order receiving and progress management to delivery, and Administration Department that conducts accounting and labor management.

Advanced Clean Facilities

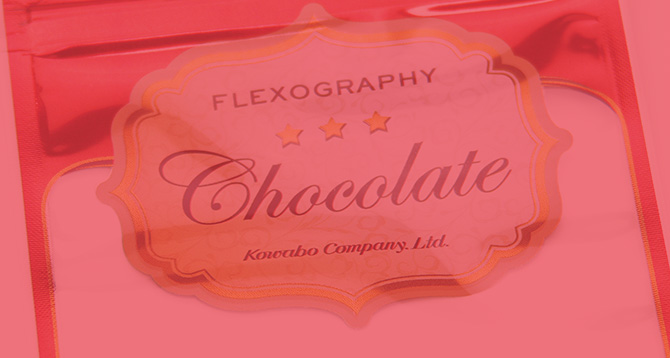

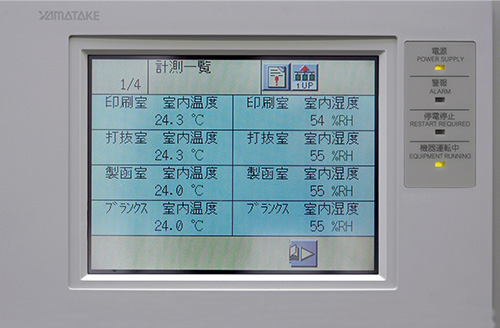

In the Production Building of the Printing Business Division, the temperature, humidity, and between-room pressure difference control is appropriately administered. This improves quality by preventing dust and blemishes and the mixing of foreign substances to allow the production of safe and clean products. The work rooms are separated according to the production processes of printing, die cutting, and folding and gluing, and each has its temperature and humidity maintained appropriately. In the Production Building, workers are subjected to air showers after putting on their work clothes and hair nets as they enter the room to prevent invasion of dirt and dust.

We have acquired ISO 9001 certification, and are promoting activities to further improve the degree of satisfaction of our clients based on the incorporation of quality measures into the processes.

Automatic shutters with interlocks

Automatic shutters with interlocks Temperature and humidity control

Temperature and humidity control Atmospheric pressure control

Atmospheric pressure control Air showers

Air showers

From Planning Proposals to Printing and Delivery

Factory Facilities

- 7-color UV offset printing press with varnish coaters

- 6-color UV offset printing press with varnish coaters

- 5-color UV offset printing press

- Press machine

- Die cutter

- Both-side full size paper inspection machine

- Both-side blanks inspection machine

- Folding and gluing machine

- CTP system

- Large-sized inkjet printer

- UV inkjet printer

- 8-color UV flexographic printing press

- Winding inspection machines

Products Line

- OTC pharmaceutical product packages

- Ethical pharmaceutical product packages

- General packaging

- Soft packaging material printing

- Cardboard boxes for transportation

- Commercial printing

- Promotional Items

- Plastic bottle forming

- Ornamental boxes

- Overseas production commissioning

- Product warehouse management (Foods)

- Products Assortment and Packaging

- Finished product inspections

- Packaged Products delivery

Access

Printing Business Division

Factory & Nagoya Sales Office

14-71, Yasui 4-chome, Kita-ku, Nagoya, Aichi 462-0023, Japan

Nagoya Sales Section, Printing Business Division, Kowabo Co., Ltd.

Tokyo Sales Office

6th Floor, Kowa Tokyo Branch 2nd Building, 4-10, Nihonbashi-honcho 3-chome,

Chuo-ku, Tokyo 103-0023, Japan

Tokyo Sales Section, Printing Business Division, Kowabo Co., Ltd.