Challenging Printing of Soft Packaging Materials using UV Flexographic Printing

Printing of soft packaging materials using UV flexographic printing presses,

which is uncommon even in Japan

Features of UV Flexographic Printing

In the Japanese soft packaging material printing industry, photogravure printing still comprises the mainstream.

However, we took note of and quickly introduced environmentally friendly UV flexographic printing, which was not popular in Japan when it was initially introduced, as an epoch-making soft packaging material printing method.

Compared to photogravure printing and other printing methods, the UV flexographic printing presses that we introduced have the following features.

- Flexographic printing is widely utilized for printing in the soft packaging materials field in Europe and America.

- Utilizing cold foiling enables in-line foil transfer and partial window-making. Compared to pastor processing, delivery time can be shortened.

- Following the advancement of technology, fine characters can be stably reproduced with precision, and delicate multi-color expression at high resolutions is possible.

- Production of multiple products in small quantities can also be supported, responding to the needs of small-lot production.

- Reproducing detailed characters, because the printing uses an finer outline unlike photogravure printing, even small detailed characters with edges can be clearly printed.

- A variety of surface processing is available, and special processing including pseudo-embossing and LC holograms can also be applied on films.

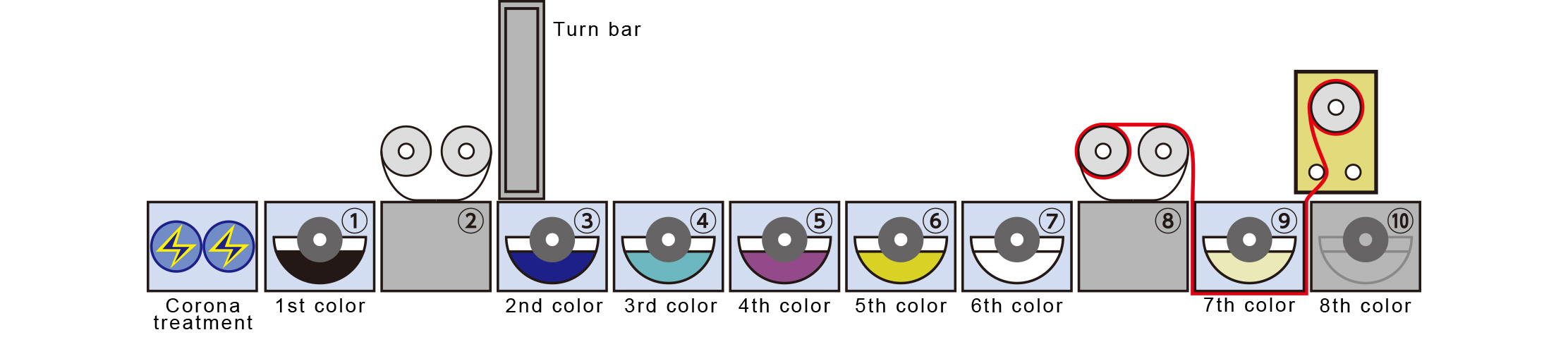

Introduction to UV Flexographic Printing Press(8-color presses)

Mechanisms of UV Flexographic Printing

Flexographic printing is a letterpress printing method in which ink is transferred to the printing material by attaching ink to the raised portions of plates made from a flexible resin material via an anilox roller.

Because the plates have elasticity which allows for printing while adjusting the printing pressure, a highly flexible printing reproducibility is realized even when using papers such as cardboard and corrugated cardboard with irregular surfaces, cloth, and the like.

Printing is also possible on thin materials that have elasticity and on films with variable thicknesses, and we incorporated this method for printing on soft packaging materials from an early stage.

The method enables a wide variety of special processing, including cold foiling (foil transfer), lamination (pasting of laminating films and attaching of hologram films), and pseudo-embossing to be implemented in-line. Because the method enables an integrated production line from printing to processing, this can be reflected in the total cost.

Features of UV Flexographic Printing Presses

Processing Variations

The main feature of UV flexographic printing is that it allows special processing such as cold foiling and pseudo-embossing (see the following figures) to be implemented in-line.

Compared to the soft packaging material printing method used until now, the design variations have been greatly broadened.

Cold Foiling

Cold foiling uses foil that can be transfered without adding heat, so it can be applied even on film materials that are sensitive to heat. It supports batch processing of window-making on soft packaging materials.

High Quality

UV flexographic printing can support the printing of extremely small and fine characters (of around 2 point size) and complicated designs. With this method, we can fulfill your detailed requirements which you had previously considered to be too difficult.

Eco-friendly

The content of volatile organic compounds (VOC) in flexographic UV ink is extremely low, and the printing method is considerate both to people and to environment. Additionally, flexographic printing has fewer losses compared to other printing methods, which also contributes to reducing the amounts of waste products.

Example of UV Flexographic Press Printing Processes

Printing is available using up to 8 colors, or up to 6 colors for cold foil processing.

Specifications and Various Details of UV Flexographic Printing Presses

- Basic Specifications

- Line type 8-color press (No. of units: 10) both-side printing, UV printing method

Cold foiling (using foil) - Paper Width and Acceptable Printing Width

- 150mm to 520mm Please consult us for sizes bigger than that given

The acceptable width is 490mm - Printing Inks

- UV inks (Ultraviolet hardening type, non-solvent, low-odor inks)

* Support is available for various papers, films, and added value.

* Support is available for various types of special inks.

Clients who would Benefit from our Proposals

- Clients who wish to print text attractively

- Clients who place particular importance on high quality

- Clients who wish to print small lots

- Clients who wish to shorten delivery time for processing such as window-making

- Clients who wish to discuss about soft packaging materials